Silicon carbide fiber has the advantages of high temperature oxidation resistance, high hardness, high strength, high thermal stability, corrosion resistance and low density. It is one of the most ideal aerospace high temperature resistant, reinforcing and stealth materials. It also has small Neutron absorption cross-section, so it has broad application prospects in aviation, aerospace, nuclear energy and other fields.

- 1. Technical high ground of high-temperature structural materials for aero-engines

High thrust-to-weight ratio is the goal that advanced aerospace engines are constantly pursuing. As the thrust-to-weight ratio of the engine increases, the turbine inlet temperature continues to increase, and the existing high-temperature alloy material system is difficult to meet the requirements of advanced aerospace engines. For example, the turbine inlet temperature of existing engines with a thrust-to-weight ratio of 10 has reached 1500°C, and the average turbine inlet temperature of engines with a thrust-to-weight ratio of 12 to 15 will exceed 1800°C, which is far beyond the use temperature of high-temperature alloys and intermetallic compounds. At present, the working temperature of nickel-based high-temperature alloy materials with the best heat resistance can only reach about 1100°C. The operating temperature of SiCf/SiC can be increased to 1650°C, and it is considered to be the most ideal hot-end structural component material of aerospace engines.

In developed aviation countries such as Europe and the United States, SiCf/SiC has been practically used and mass-produced in aero-engine static parts, including M53-2, M88, M88-2, F100, F119, EJ200, F414, F110, F136 and other models. Military/civilian aircraft engines.

Although my country has listed silicon carbide ceramic matrix composite (CMC-SiC) application technology research as a key development area since the 1980s, and in January 2022, an aerospace engine built by NPU using domestic new ceramic matrix composite materials The integral turbine disk successfully completed its first flight test verification. This is also the first domestic air flight test of a ceramic matrix composite rotor assembly platform, marking another important breakthrough in the key technology of our aeroengine. However, so far, the application scope and cumulative assessment time of CMC-SiC in my country are very limited, and there is a huge gap with foreign engineering application research.

- 2. Stealth materials compete for high-tech armaments

With the rapid development of modern radio technology and radar detection systems, stealth technology, as an effective means to improve the survivability and penetration capabilities of weapon systems, especially deep strike capabilities, has become a hot topic among military powers competing for high-tech armaments. The use of stealth material technology is currently the most effective and feasible means of radar stealth. For stealth materials used in special environments, in addition to reducing basic conditions such as detectability, the materials are also required to have good thermal stability and corrosion resistance. For example, the engine tail nozzles, wing edges and other parts of high-speed flying stealth fighters will face the test of high temperature oxidation and repeated high and low temperature impacts. SiCf/SiC not only has excellent mechanical properties, oxidation resistance and longer high-temperature service life, but also has good wave-absorbing properties, which meets the requirements of high-temperature parts of weapons and equipment such as the surface of supersonic aircraft, engine tail nozzles, and cruise missile noses. Stealth requirements, broad application prospects.

- 3. Small neutron absorption cross section, showing great power in the field of nuclear reactors

With the increasing emphasis on reactor safety issues, almost all zirconium alloy combustion elements used in current commercial water reactor nuclear power plants have been reconsidered, and new fuel elements using silicon carbide as cladding or matrix materials have become a new research hotspot. Fuel elements are the core components of nuclear reactors, and their performance indicators directly affect the safety and economy of the reactor. SiCf has excellent properties such as high temperature strength, high hardness, good wear resistance, good thermal shock resistance, high thermal conductivity, strong oxidation resistance and chemical corrosion resistance, and its small neutron absorption cross-section, low inherent The activity and decay heat make it suitable for the field of nuclear reactors, and has good application prospects in light water reactors, molten salt reactors and gas-cooled fast reactors.

Advanced technology has always been mastered by Japan and the United States

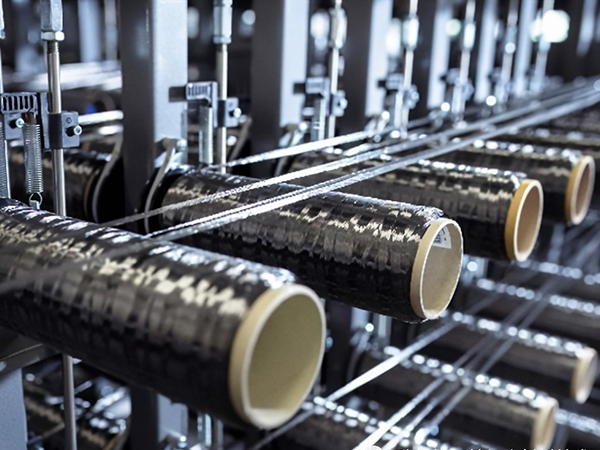

Over the past 40 years since its birth, SiC fiber has developed rapidly. According to the different fiber composition and structure, it can be divided into first, second and third generation fibers. The first generation is high oxygen carbon content silicon carbide fiber, and the second generation is Silicon carbide fiber with low oxygen and high carbon content, the third generation is silicon carbide fiber with near stoichiometric ratio. In the development process of SiC fiber, countries such as Japan and the United States have always taken the initiative in competition.

Breakthrough of the first generation of SiC fibers

In the 1980s, our country realized that silicon carbide fiber, as a new material, had potential application value in the aerospace field, so it started early, planned in advance, and specially organized relevant scientific researchers from the National University of Defense Technology to establish a SiC fiber research group.

After 2000, my country entered the application research stage of the first generation of SiC fibers and began arduous research and industrial development of independently developed SiC fibers.

In 2005, with the promotion of Jiangsu Province and Suzhou Municipal Government, the industrial development of high-temperature-resistant continuous silicon carbide fiber was implemented, and a strong scientific research team was formed. Through hard work and independent research and development, the key core equipment was self-made and became It is the first domestic company to achieve continuous production of silicon carbide fibers, breaking the long-standing technical blockade and product monopoly of Japan, the United States and other countries on this type of military-sensitive materials.

Catching up with second-generation continuous SiC fibers

In the past 10 years, the development of aerospace engines has put forward clear demands for high-temperature-resistant continuous SiC fibers, which directly promoted the development of engineering technology for second- and third-generation SiC fibers.

In response to the shortcomings of the first-generation SiC fiber's high oxygen content, which prevents the long-term use temperature in the air from exceeding 1050°C, the National University of Defense Technology launched key technology research on the second-generation SiC fiber. While maintaining the reactivity of polycarbosilane, by optimizing the composition and structure of polycarbosilane, we have made breakthroughs in the synthesis of high softening point polycarbosilane with good spinnability and oxygen-free non-melting treatment technology, and optimized the pre-burning and final firing processes. Mastered the second-generation continuous SiC fiber engineering preparation technology with independent intellectual property rights.

During the "Twelfth Five-Year Plan" period, a total of more than 600 kilograms of second-generation continuous SiC fibers and fabrics were provided to AVIC, Aerospace Science and Technology Group and other user units, which initially met the urgent demand for second-generation continuous SiC fibers for advanced aerospace engines and others.

So far, continuous SiC fiber has made great progress in product types, performance and output, and has initially broken through a series of foreign blockade measures that imposed an embargo on the preparation technology, process equipment and products of continuous SiC fiber.

The sword points to the third generation SiC fiber

In order to further improve the high-temperature performance of domestic SiC fibers, the National University of Defense Technology has launched the development of third-generation SiC fibers. The third-generation fibers developed by the National University of Defense Technology mainly include KD-S and KD-SA. The former is mainly used in the field of advanced nuclear energy, and the latter is mainly used in high-temperature structural materials. KD-S fiber uses a hydrocalcining method to remove carbon, has a near-stoichiometric composition, and has a tensile strength greater than 2.5GPa. KD-SA fiber adopts a preparation route similar to Tyranno SA fiber. The precursor polyaluminocarbosilane is prepared from low molecular weight polycarbosilane and aluminum acetylacetonate or aluminum chloride. KD-SA fiber has made great progress and has strong strength. Greater than 2.2GPa, the tensile modulus reaches 380GPa. In addition, in order to meet the demand for high-temperature stealth structural materials, the National University of Defense Technology has also conducted research on absorbing fibers.

R&D and industrialization forces are gradually growing

In recent years, many units have begun to engage in the research and production of silicon carbide fibers. They have also built a pilot research equipment platform for continuous SiC fibers and developed second-generation SiC fibers using electron beam irradiation cross-linking technology. The H2 reduction method was used to study the preparation of fibers with near stoichiometric ratios using a preparation route similar to Japan's Hi-Nicalon S fiber. Continuous SiC fiber samples have been produced. At the same time, a route similar to Tyranno SA was also used to prepare Si-Al-C fibers. preliminary exploration.

Driven by the social and economic benefits of continuous SiC fibers, companies have also begun to join in the development of continuous SiC fibers and develop continuous SiC fiber products. At present, the production of the first-generation continuous SiC fibers at the ton level has been achieved.

With the accelerated development of modernization of national defense, military power and weaponry technology, high-performance fibers have developed rapidly in various fields. As a representative of high-performance fibers, silicon carbide fiber has excellent high-temperature resistance, corrosion resistance, Wave absorption has received widespread attention.

Although we have been blocked by technology for decades, fortunately we have never given up catching up. At present, some of my country's silicon carbide fiber preparation technology levels are close to the international advanced level, but overall, there is still a certain gap between my country and foreign countries, especially in the realization of industrialized production. Silicon carbide fiber is a new national strategic reserve material, and the country is increasing deployment and investment. It is believed that in the near future, our country will gradually master the core technology of silicon carbide fiber and realize the industrial production of silicon carbide fiber.